Mrs.Hou

+86-022-87987163

+86-18202289663

18202289663@163.com

18202289663

18202289663@163.com

Monday to Sunday: 8: 30 ~ 18: 00

Tianjin North Star Technology Co., Ltd. is a professional equipment manufacturer dedicated to the magnetic separation industry. Relying on the international leading magnetic separation and vibration conveying technology, it aims at designing and manufacturing high-performance equipment to provide the industry with high-performance and high-quality designed magnetic sorting, magnetic automation and vibration conveying equipment. With rich application experience in professional and technical fields, we can solve the problems encountered in product processing, purification and quality review for enterprises.

Contact UsHeavy Duty Electromechanical Vibratory Feeders

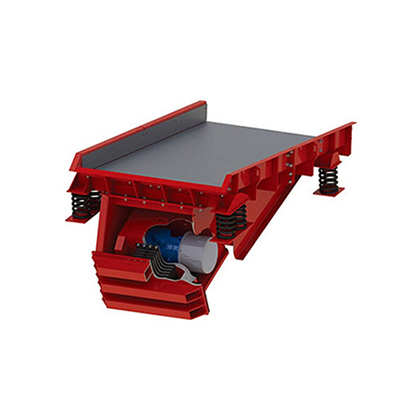

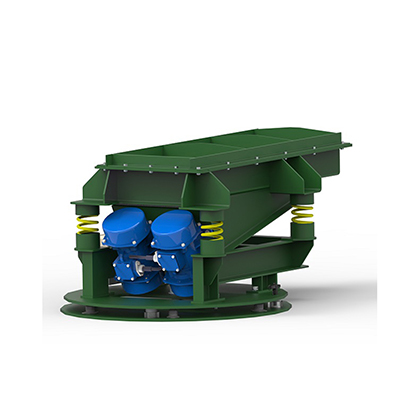

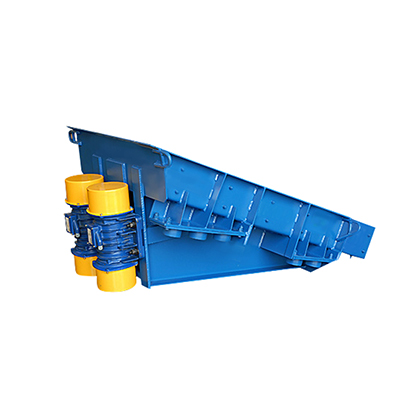

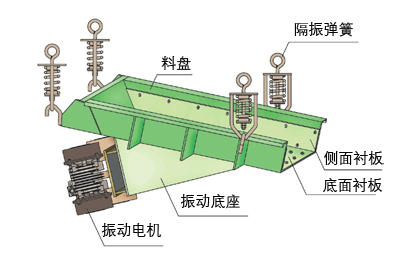

Heavy Duty Electromechanical Vibratory Feeders

Heavy duty electromechanical feeders are the heavy-weights of bulk material handling and are used for higher capacity requirements. They provide simple and efficient solutions for complex material handling operations. Adjusting the feeding speed by adjusting the voltage make the feeder stable, uniform and easy control.

Electromechanical vibrating feeders combine extra structural strength with durable components, designed for a very high flow capacity, and sometimes moist, adherent or sticky, due to its unique exciter that achieves high amplitude. Adapting dual-mass direct drive method, electromechanical models are tuned by adjusting the operating speed to obtain the exact tuning ratio. The heavy-duty electromechanical vibrating feeders only needs one rotary motor, which provides the most reliable service with the fewest parts.

Design principle

Heavy duty electromechanical feeders are two-mass, spring-connected and sub-resonant-tuned. The exciter unit is connected to the trough with corrosion resistant polymeric drive springs, which reduces the stroke vertically while amplifying stroke in the direction of material flow. This feature creates straight line motion providing maximum material flow rate and feeder capacity.

Characteristics and advantages

- Start and operate in empty or fully-loaded state

- Dependable, flexible, easily adjustable control

- Precise sub-resonant tuning ratio

- Stroke consistency and speed stability under varying headload and material damping

- Rapid and smooth starting and stopping

Optional configuration

- Various vibrator models can adapt different processing requirements

- Size and shape of the tray can be customized, multiple selection of tray materials

- Multi-drive tandem or parallel structure can be available

- Wear-resistant liners, wear-resistant coatings are available according to working conditions

Application

Heavy-duty electromechanical feeders are the heavy-weights of bulk material handling and are used for higher capacity requirements.

Material handling

Coal washery, lime processing, ore processing, wharf handling, aggregate, glass, cement, wood products and steel industry, etc.