Mrs.Hou

+86-022-87987163

+86-18202289663

18202289663@163.com

18202289663

18202289663@163.com

Monday to Sunday: 8: 30 ~ 18: 00

Tianjin North Star Technology Co., Ltd. is a professional equipment manufacturer dedicated to the magnetic separation industry. Relying on the international leading magnetic separation and vibration conveying technology, it aims at designing and manufacturing high-performance equipment to provide the industry with high-performance and high-quality designed magnetic sorting, magnetic automation and vibration conveying equipment. With rich application experience in professional and technical fields, we can solve the problems encountered in product processing, purification and quality review for enterprises.

Contact UsHump Magnets

Hump Magnets

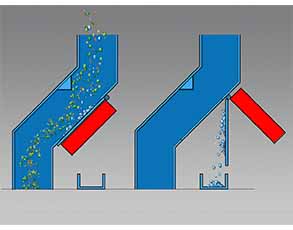

Hump magnets remove unwanted tramp metal from free-fall or air-conveying products.

The hump magnet consists of two plate magnets and a mild or stainless steel housing, two plate magnets are arranged on both sides of the V-shaped chute to ensure that the magnetic surface and material are in full contact to enhance the iron removal effect. Material is forced to change directions and then pass over a second magnet for additional ferrous removal.

Characteristics and advantages

- All mild or stainless steel construction, dust-tight enclosure

- Suitable for a variety of special environments (corrosive, food raw materials, etc.)

- Ceramic magnet circuits or rare earth magnetic circuitsis are suitable for tramp metal or fine metal

- Discharging iron outside the flow channel can avoid secondary pollution

- No wearing parts and free-maintenance

Optional configuration

- The material of housing can be carbon steel or stainless steel

- A variety of magnetic circuit and temperature tolerance criteria are available

- The size and specification of magnet plates can be customized according to requirements

- Optional inspection window to observe the adsorption of iron

Application

Hump magnets are mainly used for powder streams in free-fall or chute applications. The angle of the chute may not exceed 45° from the vertical.

Material handling

Feed, peanuts, grains, sawdust, fiberglass, plastic, rubber and other materials, etc.